Different mold for blister packaging

Let 's talk about the different mold for the blister packaging -Gypsum mold ,Copper mold and Aluminum mold

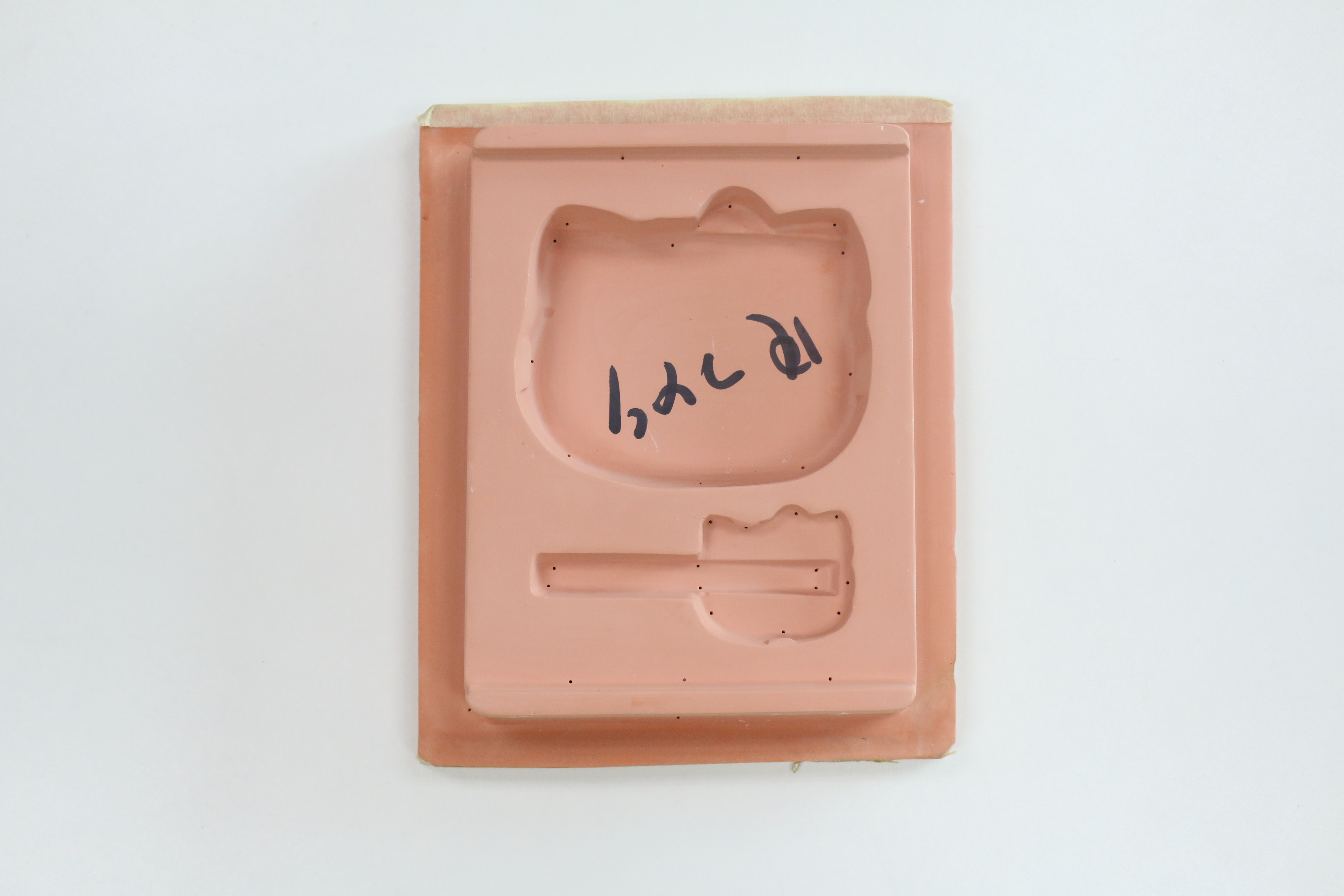

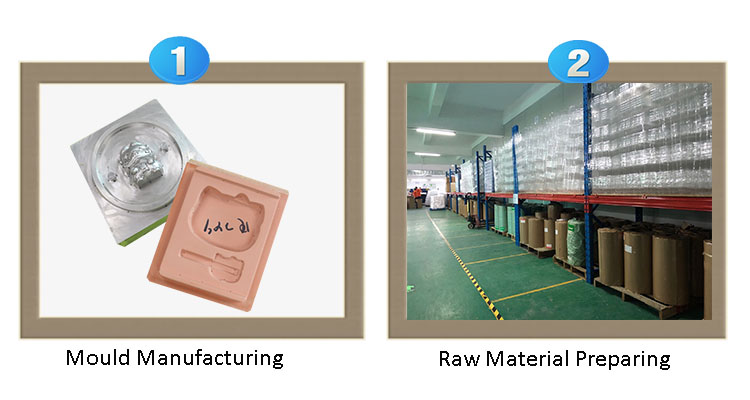

First -Gypsum mold

Just as the name implies ,gypsum mold is made of plaster ,generally it 's used for making blister packaging samples,copper mold is easy to change ,but easy to deform and low strength ,so generally we used it to making samples ,it is not good for mass production.

Second-Copper mold

It's used for mass production ,generally if the blister packaging has big cavity and low precision ,we will choose copper mold ,but the service life of copper mold is relatively short and easy to damage.

Third-Aluminum mold

Products made from aluminum molds are generally very exquisite, with good smoothness and high precision.So high surface smoothness, small spacing, high precision and irregularly shaped blister packaging ,we will choose aluminum mold , and aluminum mold has longer service life than copper mold .

When we make the blister packaging ,we will choose the mold according to customer's requirements .

Provide customers with the most economical and affordable solution.

We meet different customer's needs and incorporate them into the design of each blister package. Our packaging design team can develop a fully customized blister packaging that meets your exact specifications.We make a variety of shape Plastic Clamshell Packaging and trays which will show your product in the best way!